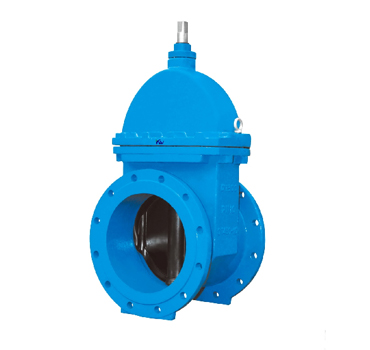

Gate valve installation method, gate valve manufacturers say.

Gate valve manufacturer

When installing the gate valve, in order to prevent metal, sand and other foreign bodies from invading the gate valve and damaging the sealing surface; It is necessary to set the filter and flush valve. In order to keep the compressed air clean, an oil-water separator or air filter should be installed in front of the gate valve. Considering that the working status of the gate valve can be checked during operation, it is necessary to set the instrument and check valve.

Gate valve manufacturers said that in order to maintain the operating temperature, set up insulation facilities outside the gate valve; For the installation behind the valve, it is necessary to set a safety valve or check valve; Considering the continuous operation of the gate valve, it is convenient to set the parallel system or bypass system.

1. Check gate valve protection facilities:

In order to prevent adverse consequences such as product quality degradation and accidents caused by leakage or media backflow after the failure of the check valve, one or two shut-off valves are set before and after the check valve. If two shut-off valves are provided, the check valve can be easily removed and serviced.

2. Implementation of safety valve protection

The cut-off valve is generally not set before and after the installation mode, and can only be used in individual cases. Remind everyone that if the medium force contains solid particles, it will affect the safety valve can not be locked after takeoff. Therefore, a lead-sealed gate valve should be installed before and after the safety valve. Gate and relief valves should be fully open and a DN20 check valve should be installed directly into the atmosphere. Gate valve manufacturer

Gate valve manufacturers said that at normal temperature, when the medium such as slow-release wax is solid, or when the medium such as light liquid is lower than 0 due to decompression gasification temperature, steam tracing is required. If it is a safety valve used in corrosive media, then according to the corrosion resistance of the gate valve, it is necessary to add a layer of corrosion-resistant explosion-proof film at the entrance of the gate valve. Usually, a gas safety valve is equipped with a bypass valve according to its size for manual exhaust.

3. Protection facilities of pressure reducing valve:

There are usually three kinds of installation facilities for pressure reducing valves. Pressure gauges are installed before and after the pressure reducing valve to facilitate the observation of the pressure before and after the valve. Install a fully enclosed safety valve behind the gate valve to prevent gate valve failure. When the pressure behind the valve exceeds the normal pressure, the system behind the valve will jump. Gate valve manufacturer

The drainage pipe is installed in front of the stop valve in front of the gate valve and is mainly used to flush the drainage channel. Some of them use steam traps. The bypass pipe is mainly used to close the cut-off valve, open the bypass valve, and manually adjust the flow before and after the failure of the pressure reducing valve. It can be cycled and then repaired or replaced with a pressure reducing valve.

4. Steam trap protection facilities:

Gate valve manufacturers said that there are two types of traps with bypass pipes and without bypass pipes, including condensate recovery, condensate non-recovery, drainage charges and other special requirements of the trap. Can be installed in parallel. Our engineers remind you not to discharge condensate through the bypass line when servicing the trap, which will allow steam to escape and return to the water system. Under normal circumstances, there is no need to install a by-pass pipe, and it is only suitable for heating equipment with strict heating temperature requirements in continuous production.