(1) Direction and position

Many valves are directional, such as flange valves, globe valves, throttle valves, pressure reducing valves, check valves, etc. If they are installed upside down, they will affect the effectiveness and life (such as throttle valves), or they will not work at all (such as pressure reducing valves), and even cause danger (such as check valves). Usually, the valve has a directional sign on the body. If not, they should be correctly identified based on how the valves work. The valve chamber of the globe valve is asymmetrical. The fluid should pass through the valve port from the bottom to the top so that the fluid resistance is small (determined by the shape), and the opening saves effort (because the medium pressure is upward), and the medium does not squeeze the body. After closing, it is repackaged for easy maintenance, which is why the stop valve cannot be reversed. Other valves also have their own characteristics.

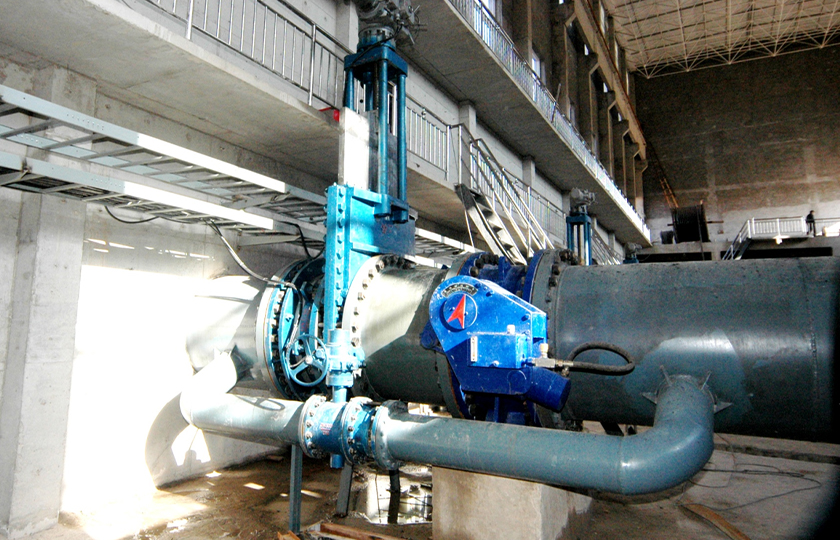

The installation position of the valve must be easy to operate: even if the temporary installation is difficult, the long-term work of the operator must be considered. It is best to keep the valve handwheel at chest level (usually 1.2 meters from the operating floor) to make it easier to open and close the valve. The handwheel of the ground valve should be upward rather than inclined to avoid awkward operation. Valves for wall machines and equipment should also leave room for the operator to stand. It is necessary to avoid operation in the air, especially acid and alkali, toxic media, etc., otherwise it is very unsafe. Do not install the gate upside down (i.e. handwheel down), otherwise the medium will remain in the valve cover space for a long time, which is easy to corrod the stem, and therefore taboo for some process requirements. At the same time, changing the packaging is very inconvenient. Exposed stem Gate valves should not be installed underground, otherwise the exposed stem will be corroded by moisture. When installing the lift check valve, ensure that its disc is vertical for flexible lifting. For swing check valves, ensure that the pins are level during installation for flexible turning. The pressure reducing valve should be installed vertically on the horizontal pipe and cannot be tilted in all directions.

Valve manufacturer

(2) Construction operations

Care must be taken in installation and construction to avoid touching valves made of fragile materials.

Before installation, check the valve, check the specifications and models, and determine if there is damage, especially the valve stem. Rotate it a few times to see if it is tilted, as the valve rod is most likely to tilt during transport. Remove debris from the valve at the same time.

When lifting the valve, do not tie the rope to the handwheel or stem to avoid damaging these parts. It should be tied to the flange.

The pipe connecting to the valve must be clean. Compressed air can be used to blow away iron oxide chips, silt, welding slag and other debris. These debris not only easily scratches the sealing surface of the valve. Larger debris, such as welding slag, can also clog small valves and disable them. When installing the spiral valve, the sealing packing should be wrapped on the pipe thread, do not enter the valve, so as to avoid the accumulation of the valve and affect the flow of the valve.

When installing flange valves, tighten bolts evenly and symmetrically. Valve flanges and pipe flanges must be parallel and leave a reasonable gap to avoid excessive pressure and even valve rupture. Special attention should be paid to brittle materials and low-strength valves, and valves that must be welded to the pipe first should be spot-welded, and then the closed part should be fully opened before being welded.

(3) Protection measures

Some valves also require external protection, i.e. insulation and refrigeration. Sometimes hot steam pipes are added to the insulation. Which valve should be kept warm or cold depends on production requirements.

In principle, if the medium in the valve cools too much, it will affect the production efficiency or freeze the valve, and it needs to be insulated or even mixed with heat; If the valve is exposed and is not conducive to production or frosting, etc., it needs to be kept low. Insulation materials include asbestos, slag wool, glass wool, perlite, diatomite; Insulation materials include cork, perlite, foam, plastic, etc.

(4) Bypass and instrumentation

In addition to the necessary protective facilities, some valves have bypass and instrumentation. The bypass has been installed. Easy to repair trap. For other valves, bypass is also installed. Whether to install bypass depends on valve condition, importance and production requirements.